Halftones and halftone printing are a critical part of the simulated process color screen printing method. Understanding halftones and halftone screens and how they are made, and work will enlighten your understanding of the halftone screen printing process.

Halftone images are images that are converted from grey scale to black dots resulting in images that consists of only black and white. White being the background color of the halftone image. Halftone images and printing are used to simulate continuous tone images with just black and white.

Color ink screen printing with halftones can also be used to simulate full color continuous tone images with a limited number of colors. This type of halftone printing is known as simulated process color screen printing.

How halftones are Processed

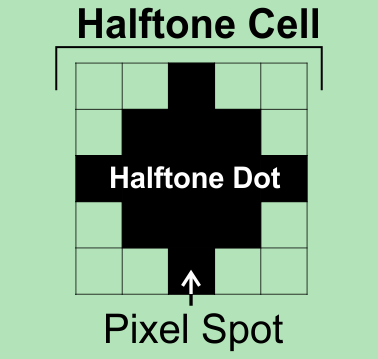

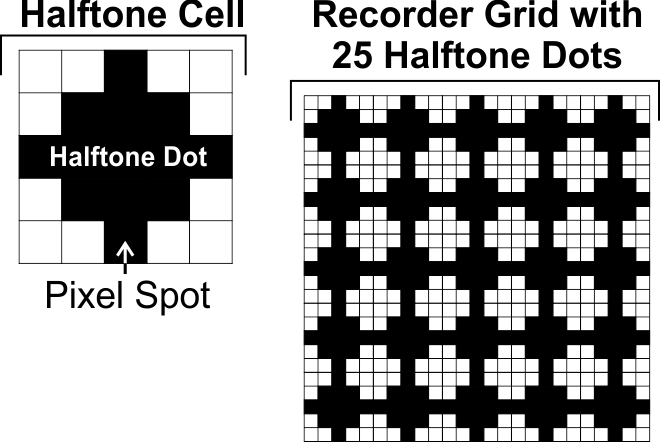

When the image is raster processed each halftone cell in the recorder grid will be scanned to determine the average black or grey scale color density or value of the halftone cell.

The 50% grey square on the left above represents the halftone cell. If the halftone cell is found to have a 50% color density. Then 50% of the pixels (pixel spots) in the halftone cell will be turned to pure black and 50% will remain white, creating a 50% halftone dot.

Notice the 6 X 6 halftone cell which would equal 36 pixel spots. 50% or 18 of the pixels spots have been turned black and 18 have remained white. Resulting is a 50% halftone dot.

NOTE - For demonstrative purposes low resolution halftone cells are used in this article. normally halftone processing is done at much higher image resolutions to provide for higher line counts, more accurate half-toning and cleaner rounder halftone dot shapes.

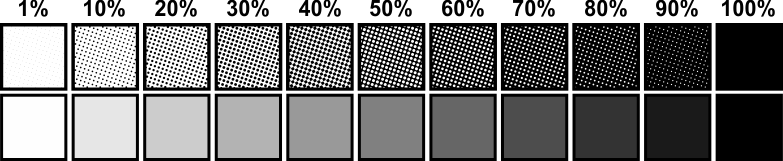

Halftone Dots and Grey Scale Density

The image above shows a simple grey scale image set up as squares with 10% incremental changes from 10% grey scale to 100% black density. The image on top has been converted to halftones. As the grey scale density increases the size of the halftone dots also increase. The larger dots simulate a darker grey scale representation

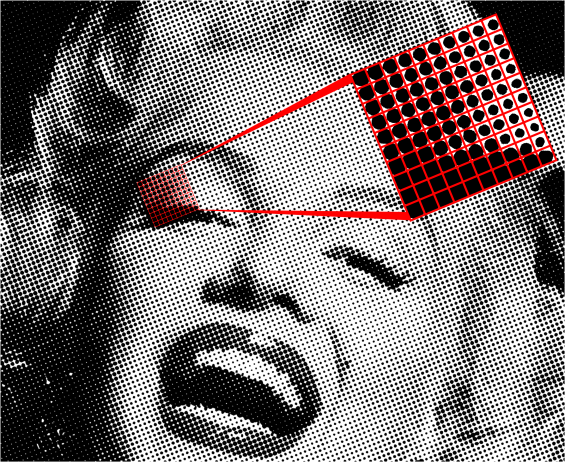

Halftone Dots and Images

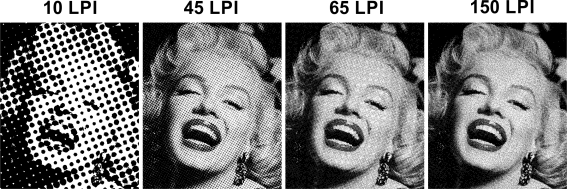

The above image of Marylin Monroe has been half-toned at a low resolution or a low LPI (lines per inch) to show how half-toning works with images. Notice the square that has been enlarged on the right side of the image. This square grid demonstrates how the halftone dots change in size based on the density value of grey scale within the halftone cells that are processed as the image is processed into halftones.

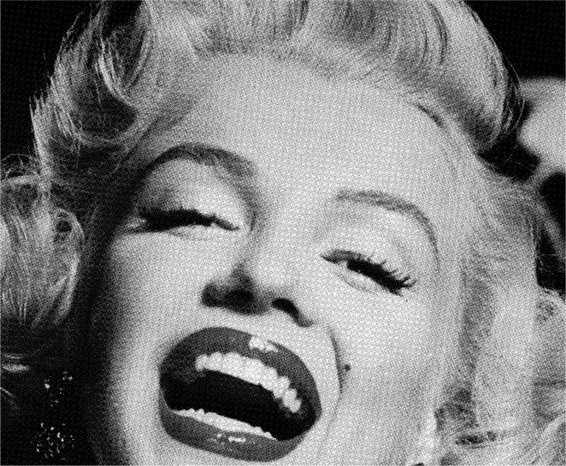

The above image is the same as the previous image of Marylin Monroe and was converted to halftones at a higher resolution or LPI (lines per inch).

Notice with the high LPI you do not perceive the dots as clearly. This image demonstrates how halftones which are comprised of various sizes of black dots simulate the appearance of a continuous tone image. You now see a smoother more grey scale looking image yet the image is only black halftone dots and white. Black being the halftones and white being the background color.

Halftones and LPI (Lines Per Inch)

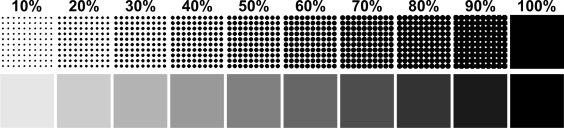

LPI or lines per inch is a variable setting in the halftone conversion process. The above grey scale chart was converted to halftones and 10 LPI. 10 LPI would process the grey scale image with ten lines of halftone cells or dots per one inch in the image being processed.

The LPI used in processing the image will affect the detail and resolution of the image. The higher the LPI selected for the halftone conversion the more lines of halftone dots will be used to process the image. High LPI halftone images produce greater detail than LPI conversions.

NOTE - LPI is also referred to as frequency in the halftone screening process.

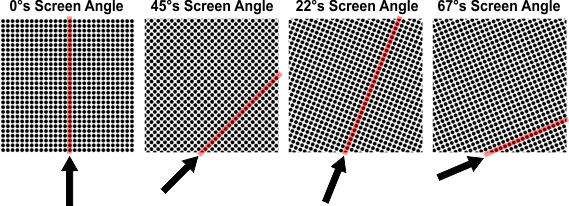

Halftone screen angle is the second option or variable in the halftone screening process. The above image displays a 50% gray scale square processed to halftones using various screen angles. Screen angles are the direction in which halftone lines will processed. Notice the arrow and red line for each image which shows the angle or direction of the halftone lines.

Screen angles are used in various forms or methods of grey scale and simulated process color screen printing. Such as rosette, flamenco and interlocking halftone printing.

Halftones and Screen Angle

Halftone screen angle is the second option or variable in the halftone screening process. The above image displays a 50% gray scale square processed to halftones using various screen angles. Screen angles are the direction in which halftone lines will processed. Notice the arrow and red line for each image which show the angle or direction of the halftone lines.

Screen angles are used in various forms of grey scale and simulated process color screen printing. Such as rosette, flamenco and interlocking halftone printing.

Halftone Printing Methods for Simulated Process Color Screen Priting

There are several halftone printing methods used for color halftone printing. We will go over 3 of them in this article. Flamenco, Rosette and Interlocking. Each of these methods have been developed to use halftone screens with color ink to simulate continuous tone color images and graphics through the halftone printing process.

Flamenco Halftone Color Printing

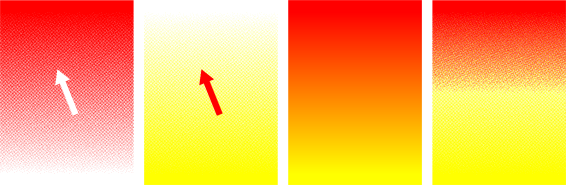

Flamenco is a color halftone printing method which prints all the halftone dots at the same LPI and Angle. In short it is a form of dot on dot halftone color printing.

The above image simulates a simple red to yellow color gradient with flamenco halftone printing. Both the red and yellow halftones are set to same LPI and 22° angle.

When comparing the actual color gradient, the 3rd image to the right against the flamenco simulation on far right we can see the gradient blend of red to yellow is not a very good reproduction of the gradient. This is due to dot on dot halftone printing. Which results in one halftone color stepping on the other and effecting the color and gradient results.

You will also notice the much of the orange in the gradient is entirely missing. Resulting in the color simulation of the gradient being inaccurate.

Rosette Halftone Color Printing

Rosette is a color halftone printing method which prints the halftone dots at same LPI with different angle °s. In short printing dots side by side with some dot over lapping.

The above image simulates a red to yellow color gradient with rosette halftone printing. The red halftone screen is set to 52°s and the yellow to 22°s. The screen are rotated at a 30° increment.

Comparing the actual color gradient in the middle with the halftone rosette simulation on the far left, once again we see the gradient is not accurate. The color blending and gradient throw orange is smoother than flamenco but sill much of orange simulation is incorrect.

Interlocking Halftone Color Printing

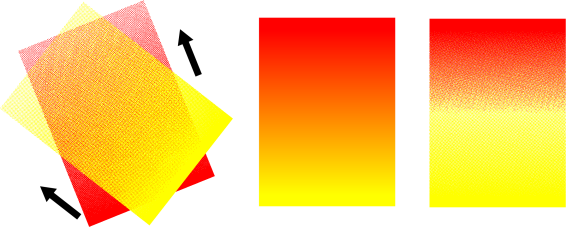

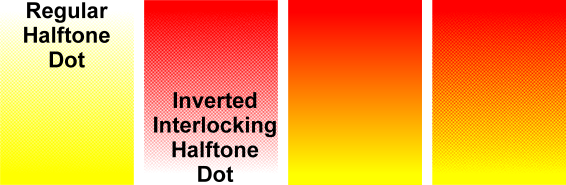

Interlocking halftone printing is the best practice for CWB simulate process color screen printing. Interlocking halftone printing prints inverted halftone dots next to regular halftone dots. The interlocking halftones then print side by side and the dot do not allow one color to be printed on top off or step on the other color.

The result is highly accurate gradient blending and color simulation when compared to flamenco or rosette halftone printing for simulated process color screen printing.

The above image simulates a red to yellow gradient with interlocking halftone printing. With interlocking the halftone dots do go over or overlap, they are side by side without any over dot lapping or color stepping on color. If you compare the original color gradient the 3rd image to the right with the interlocking halftone image the final image to the right.

You will notice that the color gradient is highly accurate and the orange color simulation from the red and yellow combined is also very accurate. This is why interlocking halftone color printing is the preferred method for CWB simulated process color screen printing.