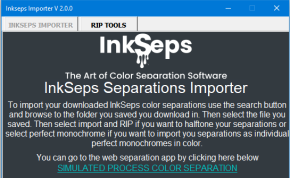

Easy Fast Cloud Based Simulated Process Color Separations

OPEN THE CLOUD BASED INKSEPS APP

Merging Colors with Gray to Reduce Colors

Why Interlocking Halftones

Watch our other free videos and read our articles to take your skills to the next level with InkSeps.

Amazing Simulate Process Color Separations Made Easy in a Web Browser.

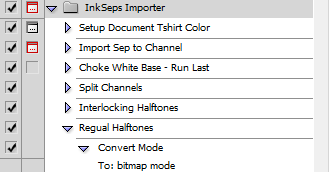

DOWNLOAD THE INKSEPS IMPORTERS

About InkSeps

InkSeps was developed for CWB Technologies by Advanced T-shirts. Check out the Advanced T-shirts website for design tools and basic to advanced free tutorial training.

CWB Technology

InkSeps color technology is based on the highly accurate CWB color model. Delivering cutting edge modern highly accurate color technology and color separations.

SimpleSeps 5 users from AdvancedTshirts.com

There is a free update for Simple 5 to work with the InkSeps 2.0 beta. You can get the free update by checking for updates from within SimpleSeps 5 or logging into your account on AdvancedTshirts.com and downloading the update from your SimpleSeps order in your account.

GO TO THE ADVANCEDTSHIRTS WEBSITE