The CWB Color Model for Screen Printing

The Color Science Behind CWB Simulated Process Printing, Ink and Ink Seps

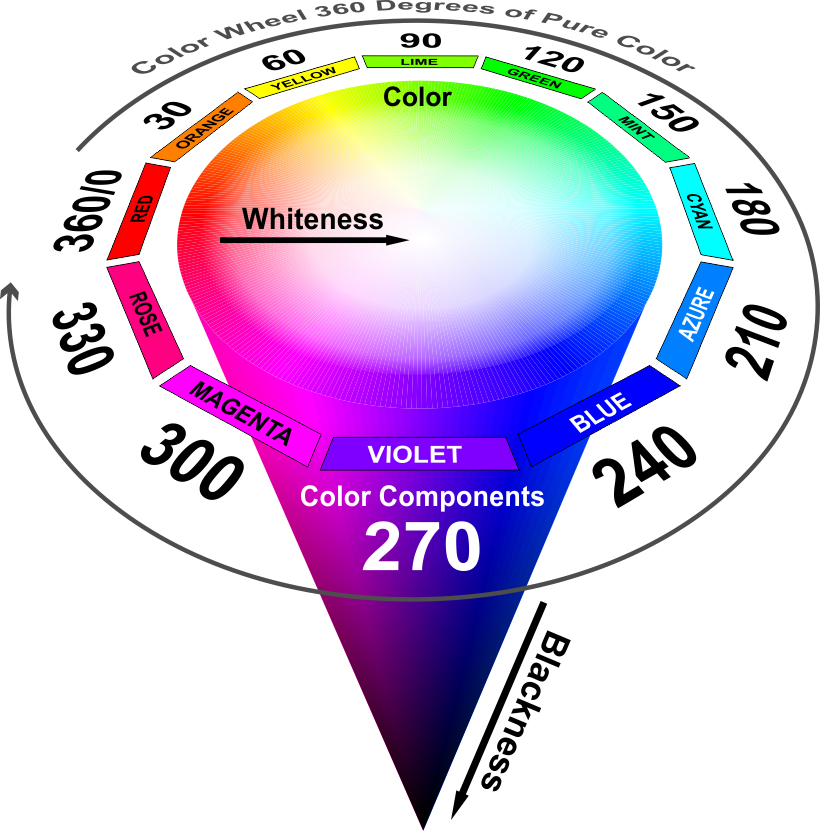

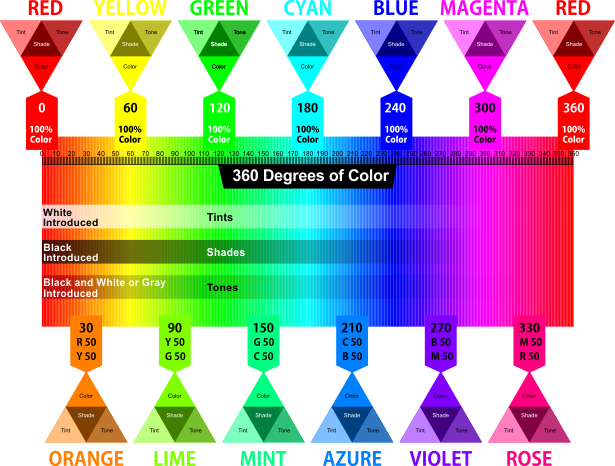

The cone shaped chart below is a simulated 3D representation of the patent pending CWB color model. The CWB color model is based on easy to understand color terms. CWB stands for Color, White and Black. The CWB color model is based 360 degrees of color (pure color or hue) and black and white.

Since screen printers with many different colors and black and white CWB is the ideal color model for screen printers.

The CWB color model is unique and simple or easy to understand as the digital color values always equal 100. The digital color values that equal 100 are also the color matching formulas for any color in percentages. CWB colors digital values based on color, white and black percentages can be used to match any color both using digital color and with any pigment based substance such as paint or ink. This same color matching capability also appliers to the screen printing process.

With the Ink Seps color separations APP the color separations are digitally 100% accurate based on the CWB color model. Going from separation to halftone simulated process color printing the CWB color accuracy is maintained. The correct CWB inks provide the best color accuracy in the printing process.

CWB is also a dynamic variable color component color model based on a foundation of 360°s of hue or pure color referred to as color in CWB as the C or color component(s). From the foundation of 360°s of color in the color spectrum. CWB color can be interactively split in 3, 6, 12 and 24 etc, color divisions or color components based on the logical division of 360°s of color. These divisions make up the variable color components of the CWB color model.

The color divisions or component degrees are -

120°s or 3 color components, cyan, magenta and yellow.

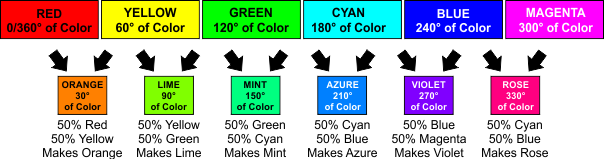

60°s or 6 color components, red, yellow, green, cyan, blue and magenta.

30°s or 12 color components, red, orange, yellow, lime, green, mint, cyan, azure, blue, violet, magenta and rose.

15°s or 24 color components, red, red-orange, orange, orange-yellow, yellow, yellow-llime, lime, lime-mint etc, as you go through the 24 color components. Additional color components such 48 or more could added.

The CWB color component beak downs result in a more understandable and easier to use color model. Because CWB color is based on easy to understand color values and color components with simple mathematical percentages that logically make sense.

In CWB all variable color components modes have digital values that are based the percentage of color or color components, plus the white and black percentages. Which when combined or added together always equal 100 or 100%.

With the CWB color model, color separation, matching and more are simplified. While at the same providing the most accurate color separation and ink products for the screen printing industry.

Breaking Down Images and CWB Color

Understanding Color with the CWB Color Model

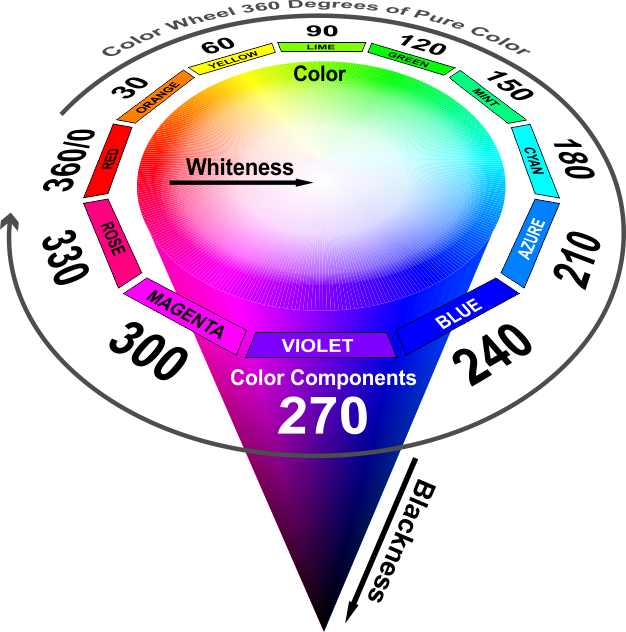

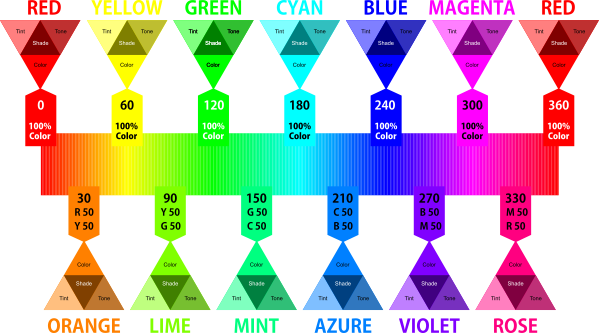

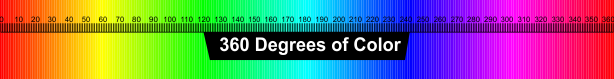

The above bar chart is simple break down of the CWB color model, 360°s of color (pure color) and the 6 and 12 color component modes of CWB color.

Color = Pure color

Tints = Pure color with white introduced or mixed with the color

Shades = Pure color with black introduced or mixed with the color

Tones = Pure color with black and white or grey introduced or mixed with the color

All images and graphics are comprised on these four states of color along with black and white. CWB provides as easy to means to understand, identify and match the colors in any image.

As laid out in the CWB color bar chart CWB takes all the color in the spectrum of light into account and then divides the color into separate color components based on the logical division of 360°s of color. Then threw CWB white, black and grey are used to accurately reproduce any color, tint, shade or tone of color. Because the digital color values of CWB always equal 100 and are based on color, black and white it easy understand what type of color your working with and how to reproduce that color.

The CWB color process when combined with Ink Seps 100% accurate color separations, the correct ink colors and half-toning provides the most accurate color printing process.

CWB Color Components, Color Mixing and Color Matching.

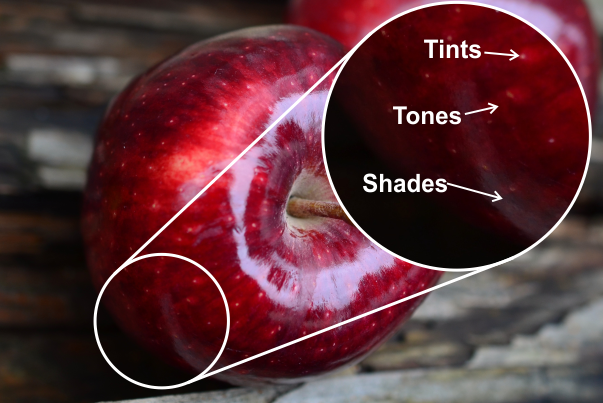

Once the foundation pure color from the 360°s color has been accurately matched, black, white or a combination of black and white can be introduced to accurately match any color, tint, shade or tone.

Providing a means to precise simulated process screen printing based on the scientifically accurate application of the CWB color model, color separations and inks.

Tints

White is mixed with pure color.

Shades

Black is mixed with pure color.

Tones

Black and white or grey are added to pure color.

Understanding the science behind the CWB color model, simulated process color separations and ink, provides the key to understanding color for screen printing. Which is why Ink Seps and CWB color is the key to successful accurate simulated process color separations and printing solution for screen printers.

Our objective with CWB color is to provide a relevant color model that is easy to understand and easily applicable to screen printing. While providing screen printers with accurate color separations, the correct ink colors and the best possible practices for accurate consistent color printing results.

Ink Seps and CWB color are a cut above the current industry standards. While other simulated process and color separation applications have no science or actual color models to define the way and process with which they handle color. Ink Seps and CWB are based on actual color science or a color model that is easy to understand, carefully thought out and well defined.