Ink coverage is a rarely discussed topic in the screen printing industry but is critical component of quality screen printing. As it is in any printing industry.

What is ink coverage?

It simple terms in and amount ink and how it is applied to a t-shirt or sub straight surface and the amount of the surface that is covered with ink.

Ink coverage effects the following aspects of screen printing.

1 - The amount of color that will be reflected back to your eyes when looking at a print. This is because screen printing based on subtractive color models. Optimized ink coverage results in more color reflection producing more vibrant prints.

2 - Cost and time of printing. If you are using more colors than you need to with flamenco printing and laying down more ink than is really needed to accurately simulate color. The cost of ink for the prints will increase as well as the amount time it takes to run the prints. Resulting in lower profits

3 - The hand or feel on the garment. If you print dot on dot or flamenco halftone with allot colors, you could lay day more than is really needed to correctly simulate color with halftone screen printing and getting more ink on the garment which would result in more hand or a heavier feeling of the ink on the garment.

Ink Coverage and Color Relectance

Color reflectance is the amount of color reflected from surfaces coated with ink, paint or other coatings.

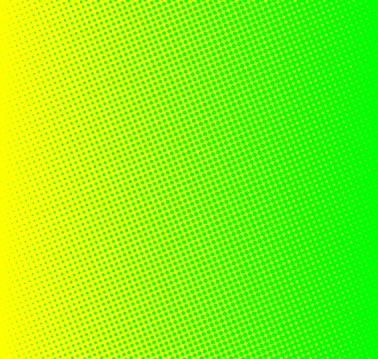

In the above chart we can see 3 halftone printing methods compared. And the difference between how light and color would be reflected from those halftone printing methods.

Interlocking halftones provide the optimal ink coverage for color relectance. This is do to the amount of ink that applied to the sub straight as dots are interlocked or side by side. Not dot on dot or over lapping dots as seen in flamenco and rosette printing.

Optimal color reflectance will result in brighter more vibrant color reflection and accuracy in the halftone screen printing process.

Ink Build Up and Print Thinkness

When printing with flamenco or rosette halftones. Dot on dot or overlapping dots will build up more ink on the garment or sub straight surface. Making the feeling of the ink on the garment thicker. This is referred to as the hand of the print.

Printing with interlocking halftones the dots are not printed dot on dot or overlapping. Resulting in less ink build up and a thinner print feeling on the garment or sub straight.

Accurate Color Simulation with Better Ink Coverage and Less Colors and Inks

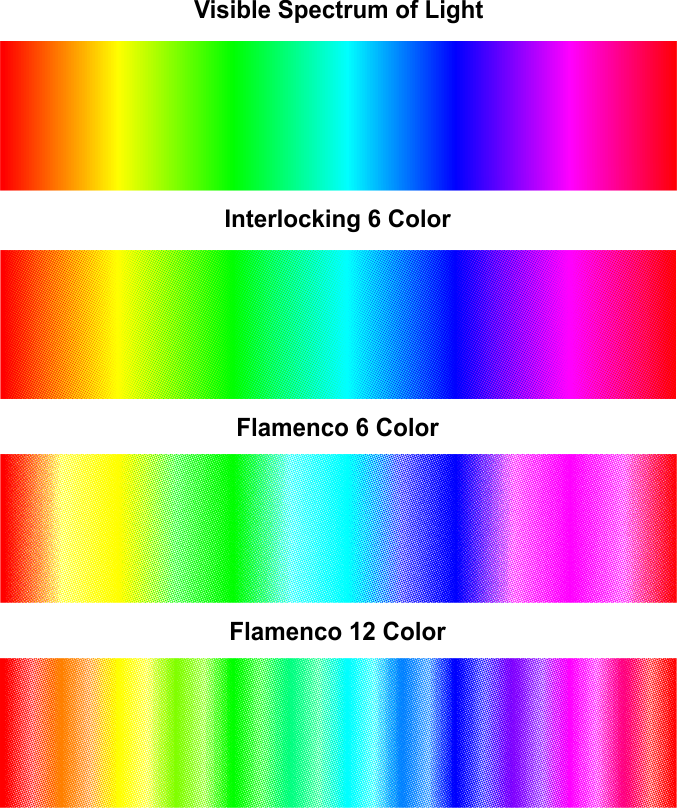

The image above starts with the visible spectrum of color. The color spectrum is the foundation for all color and color reproduction.

Below the color spectrum image are simulations of the color spectrum in both interlocking and flamenco halftone printing processes.

Notice how accurate the interlocking color spectrum simulation is. Then notice the changes in the flamenco printing method. Looking at the problems one might think to use more colors for better color simulation with flamenco.

For example in the Flamenco 12 color image orange is used in an effort to get a better quality orange simulation but the results while closer are still not as accurate as interlocking halftone color simulation with only 6 colors.

Optimized interlocking halftone printing allows you to print with better in coverage for greater color simulation, color reflectance, and accuracy with less colors. Resulting in reduced ink costs and a reduced number of colors to be printed, resulting is reduced print run times. Saving you time and money.